The experience we gained over forty years in the food packaging sector has allowed us to develop solid technical skills. Our mechanical and engineering know-how allows us to maintain high-quality standards and pay particular attention to our customers’ needs.

We can count with both an active case history of more than 1,000 customized moulds and a reliable team of technicians and engineers who support our customers and follow step by step every project-development phase.

High technological investment and attention to each phase of the production process mean that our heat sealers are able to meet the varied needs of a constantly growing market and, therefore, are an expression of the most authentic MADE IN ITALY.

TOP SEALING

This kind of packaging consists of sealing a film on the top of the tray.

Creating a protective barrier, the process grants food safety, as it prevents contamination from external agents. The sealing all around the tray profile ensures safe transport, avoiding any leak of the product during the handling process.

This solution does not imply the use of packaging technologies that could increase the durability of the products. Therefore, it is the ideal solution for those foods that for their nature or destination of use do not require a shelf-life extension.

GAS FLUSHING

This packaging technology implies the injection into the tray of a mixture of inert gasses right before the sealing process.

The type of gas and the injection time could vary depending on the type of food to be packed. This process, combined with the hermetical sealing of the tray, can contain the natural product degradation and reduce the oxygen residual inside the tray. The result is an increase in the shelf-life of the product.

MAP

When we talk about MAP packaging, we refer to a packaging process specifically designed to improve the storage of products and extend their shelf-life. It is a totally natural process that requires the use of specific mixtures of gases found in the air, namely Nitrogen (N2), Carbon Dioxide (CO2), and Oxygen (O2). In addition to extending a product’s shelf life, MAP technology allows preserving food properties and reducing microbial growth.

SKIN

Skin packaging allows applying to tray sealing the same technology as sous vide packaging. Initially conceived to meet the needs of the fish industry, in recent years it has seen a growing demand from other sectors such as meat and dairy.

During the packaging cycle, through a progressive depressurization of the vacuum chamber, the air that separates the film from the tray is completely sucked in, allowing the film to adhere completely to the product. Thanks to the high barrier, this “second skin” grants protection, maximizing the shelf-life.

Led by our technical skills, we have developed a line of thermosealing machines that combines innovation and food technology, which is also specifically designed to meet the needs of small and medium food production.

OVERSKIN

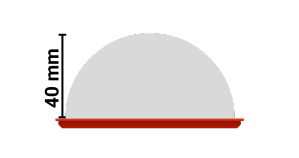

OVERSKIN technology has been conceived for the skin packaging of protruding products up to 40 mm from the edge of the tray.

This innovative system is also suitable for skin on rigid cardboard: a sustainable and recyclable packaging system with customizable graphic printing. A groundbreaking solution that grants excellent esthetical results.

Discover the solution best suited to your needs!